There are four internal Types of Losses in DC Generator that decrease efficiency of a DC generator.

1) Copper losses

2) Eddy-current losses

3) Hysteresis losses

4) Mechanical losses

|

| Types of Losses in DC Generator |

1) Copper Losses:

Copper loss is the power lost as heat in the windings; it is caused by the flow of current through

the coils of the DC armature or DC field. This loss varies directly with the square of the current

in the armature or field and the resistance of the armature or field coils.

Armature: Ia^2*Ra (armature curent square into armature resistance)

Field: If^2*Rf (field current square into field resistance)

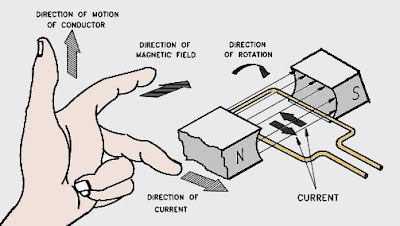

2) Eddy-Current Losses:

As the armature rotates within the field, it cuts the lines of flux at the same time that the copper

coils of wire that are wound on the armature cut the lines of flux. Since the armature is made

of iron, an EMF is induced in the iron, which causes a current to flow. These circulating

currents within the iron core are called eddy-currents

How to reduce:

To reduce eddy-currents, the armature and field cores are constructed from laminated (layered)

steel sheets. The laminated sheets are insulated from one another so that current cannot flow

from one sheet to the other.

3) Hysteresis losses :

Hysteresis losses occur when the armature rotates in a magnetic field. The magnetic domains

of the armature are held in alignment with the field in varying numbers, dependent upon field

strength. The magnetic domains rotate, with respect to the particles not held in alignment, by

one complete turn during each rotation of the armature. This rotation of magnetic domains in

the iron causes friction and heat. The heat produced by this friction is called magnetic hysteresis

loss.

How to reduce:

To reduce hysteresis losses, most DC armatures are constructed of heat-treated silicon steel,

which has an inherently low hysteresis loss. After the heat-treated silicon steel is formed to the

desired shape, the laminations are heated to a dull red and then allowed to cool. This process,

known as annealing, reduces hysteresis losses to a very low value.

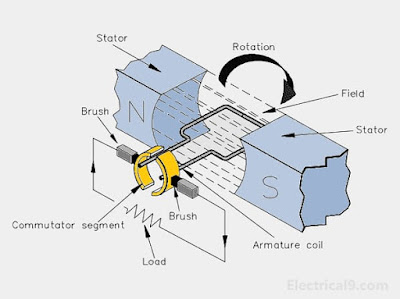

4) Mechanical losses :

Rotational or mechanical losses can be caused by bearing friction, brush friction on the

commutator, or air friction (called windage), which is caused by the air turbulence due to

armature rotation. Careful maintenance can be instrumental in keeping bearing friction to a

minimum. Clean bearings and proper lubrication are essential to the reduction of bearing friction.

Brush friction is reduced by assuring proper brush seating, using proper brushes, and maintaining

proper brush tension. A smooth and clean commutator also aids in the reduction of brush

friction.